Cold storage (-5°C to +8°C)

NIVIRA Cold storages or cold rooms are the areas which is isolated from the external environment conditions in which the ideal air is created with the help of cooling devices of the space in order to preserve the freshness of the products and intended to prolong the shelf life.

The main purpose of using cold storage or cold room is to maintain the freshness of the products extended period of time as fresh as the day it was produced without external appearance deterioration and spoiling.

According to the product that will be preserved and purpose of preservation they preserved or stored in different temperature regimes.

-5°C / +8°C is one of the most common temperature ranges for the cold storages. This temperature range covers +2°C / +8°C which is generally defined as chiller room. According to product type that will be stored in the cold rooms, the critical temperature level is determined and set. We manufacture and build chiller rooms to be used for many different product types. In the chiller room fresh fruits and vegetables, fresh meat and poultry products, milk and milk products, fresh fish and sea foods, bakery, medical drugs and chemicals are preserved.

We at NIVIRA build COLD ROOM for very different type of products such as:

Frozen storage (-18°C to -25°C)

Freezing is the solidification of the water contents of the products into large ice crystals by means of cooling below to freezing temperature. Freezing is necessary to store products to obtain extended shelf life as freezing inhibits growth of microorganisms. Frozen storage also known as freezer rooms where temperatures are set as -18°C / -21°C. During these temperatures the microbial growth of the products are totally stopped while enzymatic and non-enzymatic changes continue with a very slow rate.

The foods shall be preserved in freezer rooms (Deepfreeze Storage Rooms) after blast freezing process which is a quick-freezing carried out at -40oC. In the freezer rooms plenty different products are stored such as Frozen Fruits, Vegetables, Frozen Meats, Chicken, Fish and Frozen Bakery, Frozen foods, etc. The recommended temperature for ice cream storage is -25°C while other products can be stored -18°C / -21°C. Frozen food varieties have increased in recent years and frozen storage warehouses are also becoming very common in all over the world.

It is important to calculate precisely the cooling load so that there will be no risk of thawing during storage. Our team consists of experienced engineers and we offer effective solutions to keep foods safely and hygienically stored.

We at NIVIRA build frozen storages for very different types:

Blast Freezing (-35°C / -40°C)

Blast freezing is the process of cooling until obtaining core heat of product with a temperature of -18°C. This quick-freezing process is conducted in the -35°C / -40°C rooms. When the core heat of the product reached to -18°C, products are transferred to frozen storage rooms. -35°C / -40°C Blast Freezing is not used for storage purposes; it is only for Blast-Freezing. Important point for these rooms is that choosing proper cooling device. In order to choosing proper cooling device; product type, amount, entrance temperature, room dimensions and targeted Blast-Freezing time has to be taken into consideration. It is significant to keep Blast-Freezing time short to maintain long self-life of the products. We built plenty of blast freezing rooms taking into consideration minor details of your projects and installed the blast-freezing facilities for quite different industries such as fish, ice cream, red meat, poultry and vegetables.

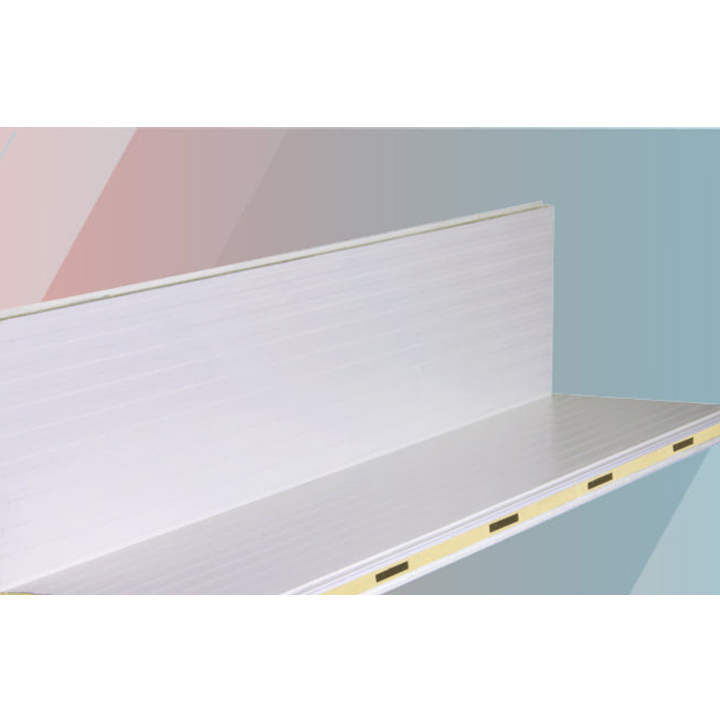

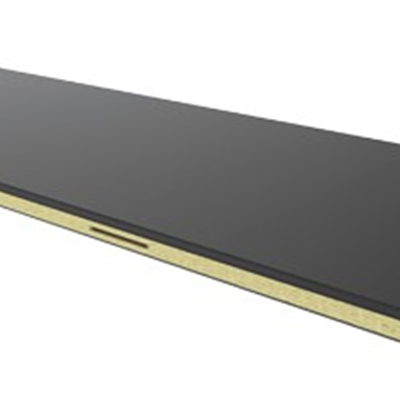

Cold Room Details

| Sr no. | PARAMETERS | DESCRIPTION |

| A | Type of cold room |

|

| B | Panel thickness | (50/60/80/100/125/150) mm |

| C | PUF density | 40 ± 2 kg/m³ |

| D | Type of floor |

|

| E | Door |

(Size:- Door/Window as per our standards) |

| F | Panel surface material |

Material – As per IS & ASTM standards |

| G | Temperature range | +15 °C to -40 °C |

| H | Corner panel | ( 300 x 300 x 8000 mm ) corner available [length as per customer requirement] |

| I | Type of panel | Discontinuous type |

| J | Thermal conductivity | 0.022 W/mk |

| K | Vapour permeability | 5.4 mg/PASM |

| L | Adhesive strength (PUF to Sheet) | 3 kg/m 2 |

| M | PUF dimension stability | Less than 2% [length, width, height only] |

| N | Type of CAM-LOCK & joint system |

|

| O | PUF insulation material | Polyurethane foam |

| P | PUF close cell | 95% ± 5% |

| Q | Compressive strength | 0.21 N/mm² (only PUF) |

| R | Water absorption | Less than 2% to 3% |